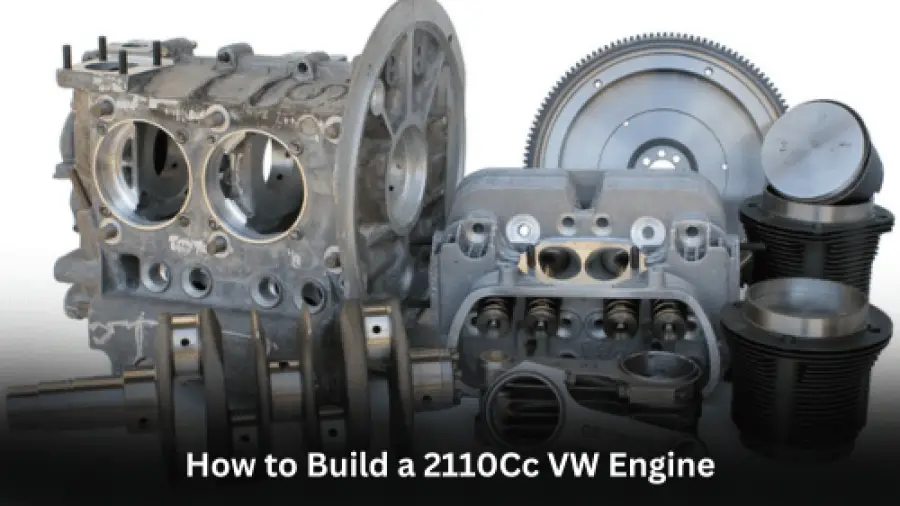

Thousands of VW fans build their own engines every year. How to Build a 2110Cc VW Engine? The process isn’t as difficult as it may seem at first, and with the right instructions, anyone can do it.

- Remove the engine from the car

- This can be done by disconnecting the negative battery terminal, draining the coolant, removing the drive belts, and unbolting the engine from the mounts

- Disassemble the engine

- This includes taking off the heads, removing the pistons and rods, and separating the crankcase halves

- Clean all of the parts

- This step is important to remove any dirt or debris that could cause problems later on

- Inspect all of the parts for wear or damage

- If any parts are damaged, they will need to be replaced before reassembling the engine

- Begin reassembling the engine by putting togetherthe crankcase halves and installingthe crankshaft and connecting rods

- Then installthe pistons and heads

- Put th eengine back in t he carand reconnectall of th e cablesand hoses that were removed during disassembly

- Fill up th e enginewith oil an dcoolant , start it up , an dcheck for leaks

How to Build a 2110Cc VW Engine?

Constructing a Volkswagen engine with a displacement of 2110cc demands extensive mechanical expertise and knowledge. Although the following is a simplified summary of the procedure, it is strongly advised to consult reliable resources or seek professional assistance for more comprehensive instructions.

- Disassembly: Begin by disassembling the original VW engine, carefully removing all components while labeling and organizing them for later reassembly.

- Crankshaft and Pistons: Upgrade the crankshaft to a 78mm stroker unit and select suitable pistons, ensuring compatibility with the increased displacement. Properly install and balance these components.

- Cylinder Heads: Choose performance cylinder heads with larger valves and porting work to improve airflow. Professional porting and valve seat work are typically recommended for optimal performance.

- Camshaft and Lifters: Select a performance camshaft and matched lifters designed for the desired power range and driving characteristics. Follow the manufacturer’s instructions for proper installation and timing.

- Intake and Exhaust: Upgrade the intake and exhaust systems to match the increased displacement. Consider options like dual carburetors or fuel injection, along with appropriately sized headers or exhaust systems.

- Cooling and Lubrication: Ensure the engine has proper cooling by upgrading the oil cooler, using a high-flow oil pump and installing an external oil cooler if needed. Proper lubrication is crucial for engine longevity.

- Fuel and Ignition: Upgrade the fuel system with high-flow components, such as a larger fuel pump and suitable injectors or carburetors. Select an ignition system that matches the performance requirements and upgrade as needed.

- Reassembly: Carefully reassemble the engine, following proper torque specifications and using new gaskets and seals. Take extra care during the assembly process to ensure everything is correctly aligned and secured.

- Tuning and Testing: After the engine is assembled, it’s crucial to perform proper tuning and testing. This includes setting the timing, adjusting carburetors or fuel injection parameters, and verifying optimal performance through thorough testing and adjustments.

It’s important to note that building a high-performance engine requires attention to detail, precision, and proper tuning. It’s recommended to consult experts, references reputable resources, or consider professional assistance to ensure a successful build.

What is the Horsepower of a Vw 1600Cc Engine?

The VW 1600cc engine is a 1.6-liter 4-cylinder engine that produces 115 horsepower and 130 lb-ft of torque. This engine was introduced in the 1967 model year, and it was used in the VW Beetle until 2003. The 1600cc engine is also used in the VW Golf, Jetta, and Passat.

How Much Does a Vw Aircooled Engine Weigh?

If you’re looking for an answer to the question “How much does a VW aircooled engine weigh?,” you’ve come to the right place. Here, we’ll give you an in-depth look at the weight of these engines, as well as some of the factors that can affect it.

First things first, let’s talk about the weight of a standard VW aircooled engine.

These engines typically weigh between 150 and 200 pounds, depending on their size and configuration. However, there are a few factors that can affect this number.

For example, if your engine has been modified or tuned in any way, it may be heavier than a stock engine.

Additionally, the weight can also vary depending on the materials used in construction. For instance, an all-aluminum engine will be lighter than one made with cast iron components.

Now that you know a little bit more about how much these engines weigh, let’s talk about some of the reasons why weight is important.

First and foremost, it’s worth noting that a heavier engine will typically require more power to run properly. As such, if you’re planning on adding horsepower to your vehicle by installing a larger or heavier engine, keep this in mind when selecting your parts.

Additionally, the weight of your engine can also have an impact on fuel economy.

Heavier engines tend to be less efficient when it comes to converting fuel into energy, which means they’ll consume more gas over time. If you’re looking to save money at the pump, then opting for a lighter engine may be the way to go.

Why is the Vw Engine in the Back?

Volkswagen has a long history of putting its engines in the back of its cars. This layout is often referred to as a rear-engine, or RR, configuration. There are a few reasons why Volkswagen has traditionally used this layout.

One reason is that it can improve weight distribution and help with traction. With the engine in the back, more weight is placed over the drive wheels, which can help with grip on slippery surfaces or when accelerating hard out of corners. The other main reason is packaging. Can I Use Starter Fluid on a Fuel-Injected Engine? By putting the engine in the back, it frees up space in the front of the car for things like passengers and luggage.

Of course, there are downsides to this layout too – one of which being that it can make a car quite difficult to handle if you’re not used to it. Another potential issue is that if you have to brake hard or swerve suddenly, all that weight at the back can cause the rear end of the car to swing out (known as oversteer). But overall, Volkswagen seems happy with its decision to keep its engines in the back!

What is a Vw Engine Made Of?

Volkswagen engines are made of a variety of materials, including aluminum, cast iron, and steel. The company uses both inline-four and boxer-six engine configurations.

Aluminum is used for the engine block and cylinder head in many VW engines.

This metal is lightweight yet strong, making it ideal for use in vehicle engines. Cast iron is another common material used in VW engines. It is often used for the crankshaft, connecting rods, and pistons.

Steel is also used throughout VW engines, particularly in the valve train components such as valves and springs.

The specific materials used in a given VW engine depend on its configuration and intended purpose. For example, racecar engines may use different materials than those found in a passenger car engine.

Ultimately, Volkswagen engineers select the materials for each engine based on factors like strength, weight, heat resistance, and durability.

Read related resources: How to Spot a Fake German Helmet?

Which of the Following Cloud Services Does Evernote Provide?

How to Dispose of a Broken Crystal?

Which VPN Solution Allows the Use of a Web Browser?

How to Do Level 81 on a Brain Test?

2110Cc Vw Engine for Sale

Are you looking for a 2110cc VW engine for sale? You may be able to find one at a salvage yard or through a private seller. Here are some things to keep in mind when searching for this engine.

The 2110cc VW engine was used in many different models of Volkswagen cars, including the Beetle, Karmann Ghia, and Bus. This engine was also used in other vehicles such as the Porsche 914 and the Audi 100. The 2110cc VW engine is a four-cylinder, air-cooled engine that was first produced in 1968.

This engine is not as common as the 1600cc or 1800cc engines, so it may be difficult to find one for sale. When searching for a 2110cc VW engine, it’s important to know which model of car it will fit in. The dimensions and bolt pattern of this engine are different than other VW engines, so it’s important to get the right one.

You may be able to find a 2110cc VW engine for sale at a salvage yard or through a private seller. If you’re buying from a private seller, make sure to ask plenty of questions about the condition of the engine and whether or not it has been rebuilt. It’s also important to get an idea of how much mileage is on the engine.

If you’re looking for a 2110cc VW engine for your car, keep these things in mind during your search!

Vw Engine Building

If you’re a Volkswagen fan, then you know that one of the most important parts of your car is the engine. That’s why it’s so important to build your own VW engine, so you can ensure that it’s as powerful and efficient as possible. Here are a few tips to help you get started:

1. Choose the right components. When you’re building a VW engine, there are a lot of different component options to choose from. You’ll need to select the right combination of parts based on your specific goals for the engine.

For example, if you’re looking for maximum power, you’ll want to choose high-performance cylinder heads and camshafts. On the other hand, if fuel economy is your priority, then more basic components will suffice.

2. Follow instructions carefully .

One mistake that many first-time builders make is not following instructions carefully enough. This can lead to big problems down the road, so take your time and be sure to double check everything before moving on.

3) Give yourself plenty of time .

Building an engine is not a quick process, so make sure you give yourself plenty of time to complete the project without rushing things. Rushing can lead to mistakes being made, which could cause serious issues later on.

4) Get help if needed .

If this is your first time building an engine (or even if it’s not), don’t hesitate to ask for help from experienced friends or professionals when needed.

High Performance Vw Bug Crate Engines

If you’re looking for an engine that can really power your Volkswagen Beetle, then you’ll want to check out high performance crate engines. These engines are designed to deliver serious power and torque, making them perfect for street or track use. There are a few things to consider when choosing a crate engine for your VW Bug, including displacement, compression ratio, and camshaft design.

Displacement is the first thing to consider when choosing a crate engine for your VW Bug. The larger the displacement, the more power the engine will be able to produce. However, too much displacement can make the engine sluggish and difficult to drive on the street.

A good rule of thumb is to choose an engine with a displacement that’s close to the stock engine in your car.

The next thing to consider is compression ratio. This is the ratio of air/fuel mixture in the cylinders during combustion.

A higher compression ratio will result in more power, but it can also make the engine less reliable and more difficult to start. If you’re not planning on racing your VW Bug, then a lower compression ratio might be a better choice.

Finally, you’ll need to decide on a camshaft design.

There are two basic types of camshafts: overhead valve (OHV) and flathead (F head). OHV camshafts are more efficient and deliver more power, but they’re also more expensive. Flathead camshafts are less powerful but cost less money upfront.

Ultimately, it’s up to you which type of camshaft you want in your high performance crate engine.

Conclusion

Building a 2110cc VW engine is not as difficult as it may seem. With the right tools and a little patience, anyone can do it.

The first step is to gather all of the necessary tools and parts.

This includes an engine stand, a torque wrench, head studs, pushrod tubes, gasket sealant, and new head bolts. The next step is to remove the old engine from the car. Once the old engine is out, it’s time to start building the new one.

Begin by bolting the crankcase halves together. Then install the crankshaft and connecting rods. Next, install the cylinder barrels and pistons.

After that, it’s time to install the heads. Finally, bolt on the intake manifold and carburetor or fuel injection system.

With everything in place, it’s time to start her up and take her for a spin!

Building a 2110cc VW engine is a fun project that anyone can do with a little patience and know-how.